FORD

Mighty Ford Performance crate Coyotes!

Ford Performance Parts aims to change your perception of affordable, high-performance box engines with a lineup of world-class box engines that offer the same Ford-tested durability as Ford's factory OEM engines.

You can order a new Coyote “Aluminator” box engine in a variety of horsepower ratings—with professional installation and tuning—and run.

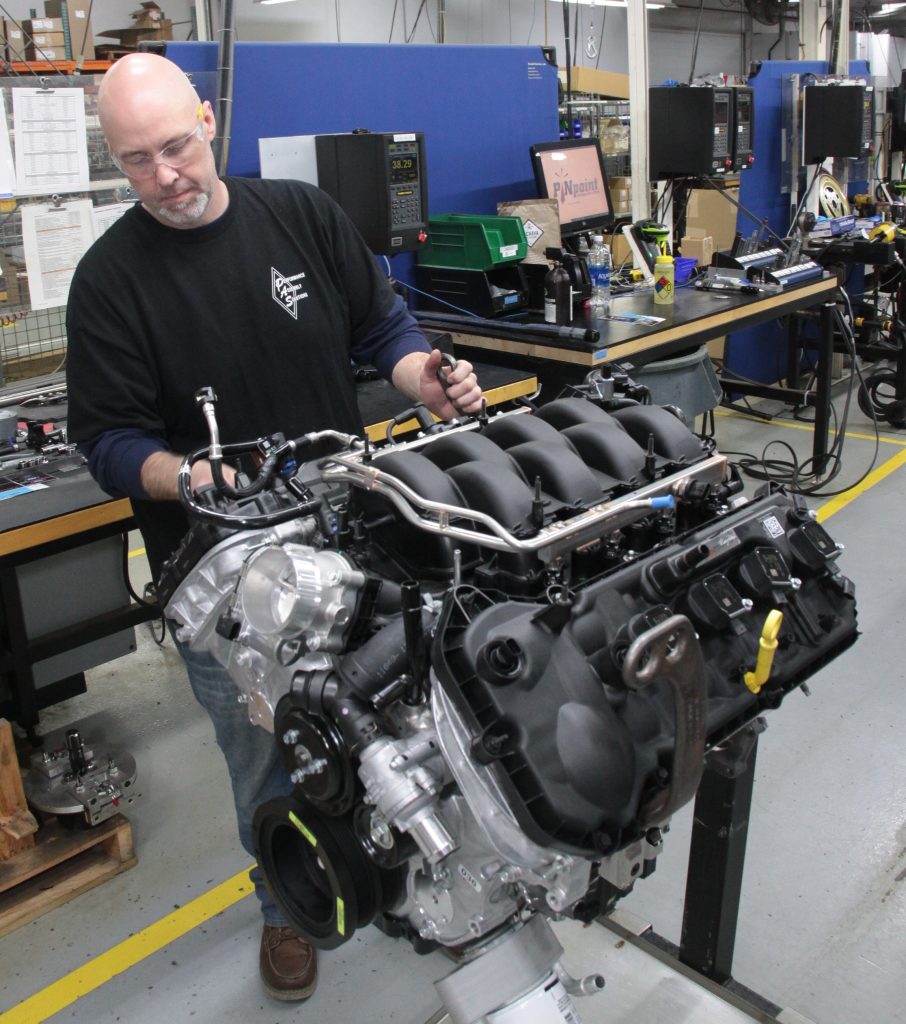

For more than a decade, Ford has sought out the expertise of Performance Assembly Solutions (PAS) in Livonia, Michigan for its powerful Coyote “factory for you” Aluminator” box engines. PAS is a division of Roush Industries, so you know the quality and durability is there. It can be said that these engines are built to Ford's own ISO 9000 engineering standards.

As we are in the 12th year of producing the Coyote, PAS is making Gen. III Direct Injection Coyote 2018-23. These engines are built to Ford's rigorous engineering standards (with proof that those standards were met during assembly) by proven engine-building professionals who build and inspect each engine on the fly. Think of PAS as a custom racing engine shop – an intimate assembly line where there's responsibility and a lot of attention to detail. These engine building professionals must prove their worth with each engine, then sign off on each job when the engine is SIM tested and checked for noise prior to shipment.

This block Gen. III Coyote was hot washed and inspected prior to entering the assembly line. The PAS line is a small, intimate business where fitters and supervisors work together. Any issues are discussed and resolved promptly. (Image/Jim Smart)

What makes these Ford Performance “Aluminator” engines world-class is a disciplined four-step build and documentation system, according to John Torvinen, Frank Hoffman and Will Clendenin of PAS. These guys tell us that this is a state-of-the-art quality control process where nothing is lost.

The first phase is a methodical disassembly, including serialization of major components. The engines arrive, are scanned and disassembled as a package. Parts don't end up in dumpsters like you see in many remanufacturing operations with piles of rods, pistons, cranks and other parts. All parts are loaded onto a dedicated cart and remain together under a common serialized barcode linked to each engine. Each block is hot washed, rinsed and dried with compressed air. Cylinder bores are cleaned with light oil to prevent corrosion.

The next phase is where the blocks, cranks, rods and pistons are measured and thoroughly inspected just as they would be by a custom engine builder, one engine at a time. Each workstation in the assembly process has a responsibility where each engine is a matter of permanent record. Block, heads and all components are linked to the same code, which means that block, crank, heads, cams and other components stay together throughout the process.

This is the most tedious phase of assembly, where the Mahle pistons are mated to the Manley H-Beam rods. Each is assembled by hand – then closely inspected for proper assembly. When the short block is being assembled, the piston and rod assemblies are re-inspected and any problems corrected. (Image/Jim Smart)

When the measurement and calibration is complete, the block is mounted on a commercial-grade engine mount, where it enters the third stage of assembly. The identification bar code is scanned into the system and each step is monitored and recorded in a database. Instructions and specifications appear on a touch screen and must be acknowledged as completed by the builder before the system will allow him to continue construction. The system also records all clamping torque data, rolling torque data, and even leak and cold test values.

Once these engines pass the SIM test and final inspection, they are packaged and packaged for shipment to Ford Performance Parts dealers worldwide. (Image/Jim Smart)

Bare blocks are equipped with new high performance main and rod bearings. Stock powder metal connecting rods and pistons are replaced for dynamic balancing and precision tuning Mahle forged Pistons and Manley H-beam Rods equipped with ARP 2000 Rod Bolts. smooth operation. After each assembly is completed, these engines are tested by SIM to check oil pressure, compression and noise. Upon completion of the SIM test, the oil is drained and the engine undergoes a final inspection prior to shipment.

Source: Jim Smart, OnAllCylinders

Nenhum comentário:

Postar um comentário