AUTONEWS

Plastic Motors May Lower Electric Car Price

Weight is the main obstacle of the electric car. Being more concrete, of its autonomy, this generated an obsession to improve the aerodynamics of vehicles and reduce their weight.

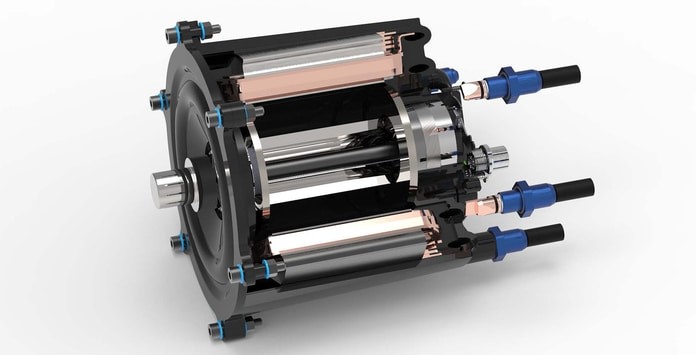

How Plastic Motors Will Work

And within that, the Fraunhofer Institute of Chemical Technology, in collaboration with the Karlsruhe Institute of Technology, has discovered a new element that can be alleviated: the electric car engines themselves.

Because they understand that by replacing the metal housing that carries it with a plastic one, it can further enhance the electric car.

In addition, it would allow 98% of the energy generated by an electric motor to be harnessed. Due to the metal housing, 10% of this energy is lost due to heat losses, and although electric car motors are already very efficient, this would make them nearly 100% efficient.

Losses occur because the metal housing guides heat into a cooling sleeve to prevent overheating. And that would be avoided with this plastic housing and flat rectangular cables replacing the round ones. This would save space allowing heat to dissipate within the engine.

The plastics used for the development of this project are thermo stable and are reinforced with fiber, which also allows to reduce production costs. In fact, according to the researchers themselves, these prototypes are built in just four minutes. Therefore, if they are as reliable as current motors, it can be a breakthrough for electric cars.

By carrying out this project, brands could make electric cars more affordable. Thus, they would solve another major complaint of the public interested in this type of mobility.

One of the challenges of the electric car is, among other things, reducing its weight, which is mainly heavier due to the batteries. Another of the heaviest components in any car is the engine, but now researchers at the Fraunhofer Institute are working with the Karlsruhe Institute of Technology to develop a new electric motor made of polymeric (plastic) materials that not only reduces The weight also reaffirms the cooling concept, further increasing the efficiency of the electric motor.

The idea is to use polymers as a material for the motor housing and to significantly increase the power density.

There are three key points that play a decisive role in improving an electric motor:

1.High power density;

2.Compact design;

3.High efficiency levels.

This project is called 'DEMIL', an abbreviation that in German stands for "Directly-cooled electric motor with integrated lightweight housing."

Renewable Energy Magazine

Nenhum comentário:

Postar um comentário