AUTONEWS

Batteries with 700km autonomy in 2025

In conventional gasoline or diesel cars, it was the sophistication of the mechanics that made them more powerful and fast, with Ferrari and Lamborghini being among the dominant builders. But if the objectives were rather low price and economy, then it was necessary to point to other type builders, those with smaller, simple and inexpensive mechanics, which with less exuberant accelerations could get more affordable prices.If this was the reality in conventional vehicles, with fossil fuel engines, in the era of electric cars everything depends on the type of battery. Anyone who has access to the most advanced technology, which allows a greater energy density, can afford to simultaneously produce a version of an electric car that is more powerful and with greater autonomy, and then, alternatively, design another more affordable version.

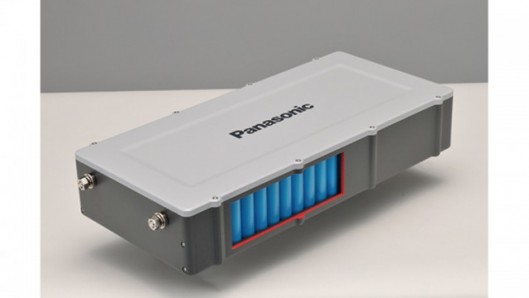

Whenever we talk about electric car batteries, it is talk of packs - essentially a large aluminum box, with cooling system - and cells. These are important because they are the ones that store the energy. To see how important they are, let us remember that the Renault Zoe had in the first version a pack of batteries with a capacity of 22 kWh. He switched it to a 41 kWh, which allowed him to almost double his autonomy. However, it maintained the 192 cells that made it and the same model, the 18650 (cylindrical and slightly larger than an AA cell, 18 mm in diameter and 65 mm high). However, due to another technology, each of them maintained the nominal voltage at 3.75V, but increased the amperage from 36Ah to 63.4Ah (192 × 63.4 × 3.75 = 45.6 kWh of total capacity, or 41 kWh useful).Another example, perhaps less impressive, is given by Tesla, which had the battery with a fixed capacity of 75 kWh.

Maintaining Panasonic's 18650 cells, with slight changes in the anode, managed to raise the capacity to 90 kWh, which allowed it to increase the autonomy and mount more powerful engines.

The novelty now comes from the side of the South Korean manufacturers of accumulators, with LG Chem, the same manufacturer of the cells for Renault, to announce that, after all, the batteries known as NCM 811, planned for within three to five years , will be available as early as 2019. And LG Chem will not be alone in this leap forward technologically, as its compatriots Samsung SDI and SK Innovation, as well as the Chinese CATL, are preparing to follow in their footsteps quickly.But not all are roses, since the 811 NCMs also seem to have some limitations. And if you want an example, look at Tesla, which uses the NCA, which continues to evolve - with Musk to show that they already use less cobalt than the future NCM 811, since at first it took 11 kg per car and now only 4.5 kg - by manufacturing them in the 18650 format for the Model S and X and 21700 for the latest Model 3. However, the American brand uses the NCM 811 technology for Powerwall accumulators, batteries stationary for domestic and industrial use, but which you prefer not to use on vehicles.The reasons that lead Tesla not to use the NCM 811 in S, X and 3, despite controlling this technology, must be related to the greater instability that the 811 have, due to reduction of cobalt and increase of nickel. After recharging the battery, the NI4 + becomes very unstable and may react unwantedly with the electrolyte. Delicate is also the possibility that lithium compounds decompose during charges, releasing gases and swelling the cells, which can burst, especially those of bag.Finally, the cathodes of the new batteries have to be produced in an inert environment, to avoid any kind of reaction with the atmosphere. Not being impossible to solve, this need will increase the cost of production, which the reduction of the amount of cobalt was intended to achieve. These are the challenges for nickel (and cobalt and manganese) batteries that have been around for a long time, and LG Chem, Samsung SDI, SK Innovation and CATL have all been able to solve them. As for Tesla and Panasonic, for their part, it appears that they will try to create the NCMA, that is, to add aluminum oxide to the cathode, to help control excess nickel.

Nenhum comentário:

Postar um comentário